Sometimes, an off-the-shelf tool is just not going to cut it—literally. Whether you have a highly specific application or are looking to shave a few crucial minutes off your turnaround times, a custom-crafted cutting tool may be just the thing you need.

If this is your first time shopping around for a custom tool manufacturer, you probably don’t know really what to expect—and that’s okay. We’re here to help.

Here are the five steps you can expect when ordering custom carbide cutting tools.

1. THOROUGHLY DISCUSS THE NEEDS OF THE TOOL

The first step of any successful tool creation is to have an in-depth conversation with your tool creation team to make sure you’re both on the same page. You know you’ve chosen a good partner if they take the time to listen to your unique machining situation, understand your challenges, and ask the right questions.

Custom tool creation questions they might ask:

- What is the specific application of the tool?

- What kind(s) of material will it be machining?

- Do you have precise dimensional data specifications?

- Will this be a prototype, short-run, or full-scale production?

2. ANTICIPATE ANY MANUFACTURING LIMITATIONS

Once the team has gathered as much information about the tool as they can, it’s time for their design engineers to consider any potential challenges that may arise during the tool’s creation. Of course, determining issues is only the first step, as they’ll need to do a little creative problem solving to find the most efficient and cost-effective solution as well.

Challenges faced when creating custom cutting tools:

- Fixturing: Will it require a custom fixture to reduce setup and cutting time?

- Holders: Will the tool need a custom adaptor to mount the equipment?

- Edge Prep: Will the tool require additional strength on the cutting edges?

- Coatings: Will the tool need material, abrasion, or thermal resistance?

3. RECIEVE A FINAL DRAWING OF THE DESIGN

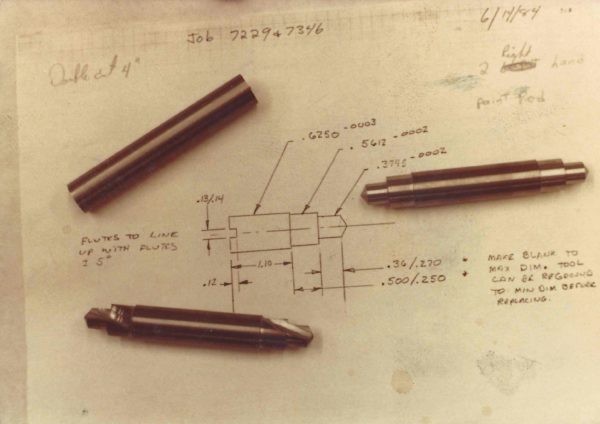

The next step is for the tool manufacturer to produce a final 2D drawing or 3D CAD design of the custom tool. If you have a rough sketch of the tool or a similar part print, be sure to send that over so they have a good place to start.

From there, the team will take all the information they gathered—as well as any additional research they conducted—to clearly define the custom tool’s dimensions, tolerances, and material specifications.

Once they have the design ready, they’ll send it to you for approval. If you have any feedback, now is the time to share it so they can make any necessary alterations before production begins.

4. AWAIT YOUR CUSTOM CUTTING TOOL’S CREATION

After you give final approval on the design, you should expect to receive two estimates: the first is a pricing quote and the second is the turnaround time you can expect. Of course, depending on the tool’s material, difficulty level, and manufacturing process, these numbers can vary quite a bit.

Once you sign on the dotted line, your tool manufacturer will determine the best method for creating and finishing your custom cutting tool.

Custom cutting tool creation

At Special Tools Inc., we use advanced grinding machines to create custom tools for our customers. These grinding machines use high-speed abrasive grinding wheels to rub away the surface material of the carbide or HSS your tool is being made from.

The grinding wheels themselves are made from extra-hard materials such as diamond or Cubic Boron Nitride (CBN). They are also used to provide a smooth tool finish and a sharp cutting edge on the completed tool.

5. FINAL INSPECTION AND DELIVERY

All tools will be inspected in-house upon completion, with sample inspections conducted for short- and long-run orders. Once the final inspection is passed, your tools will be packaged and shipped to your door.

Congratulations, you’re now ready to start machining with your custom carbide or high-speed steel cutting tools!

SPECIAL TOOLS IS YOUR GO-TO SOURCE FOR CUSTOM TOOL CREATION

If you’re a Minnesota business searching for a local tool expert you can trust, look no further than Special Tools. For three generations, we’ve been supplying our customers with the highest quality custom tools across a wide variety of industries.

Visit our website to get an estimate or give us a call at 763-753-6515 and we’ll work with you and your team to create exactly what you need to get the job done.