If you’re like most machine shop owners and operators, you rely on your tools to be razor-sharp to get the job done. Keeping those tools in good condition is the key to continued productivity and achieving the most precise results time and time again.

Are you looking for a more efficient way to sharpen and refine your tools? If so, you may want to consider using a CNC grinder.

In this article, we will discuss the basics of using a CNC grinding machine and how it can help improve your tooling. We will also provide some tips on how to get the most out of your CNC grinder. Keep reading to learn more.

WHAT IS A CNC GRINDER?

A CNC grinding machine uses computer numerical control (CNC) to create precision parts and tools. It uses a variety of rotating grinding wheels to remove material from the part or tool and is commonly used to sharpen and refine the edges of drill bits, end mills, and other custom cutting tools.

HOW DOES A CNC GRINDER WORK?

The grinding wheels are mounted on a spinning spindle, which moves up and down to create the desired cutting angle. The wheel is also rotated by a motor, which allows it to cut into the material at very high speeds.

As the wheel cuts into the material, it causes a large amount of heat to be generated. Grinding oil is sprayed on the tool and wheel to maintain a consistent, cool temperature to protect the integrity of the cutting tool. This oil is constantly filtered and chilled throughout each tool cycle.

WHAT ARE THE BENEFITS OF USING A CNC GRINDER FOR TOOL SHARPENING?

CNC grinding machines offer four key benefits over traditional methods of sharpening and finishing tools:

- CNC grinders create much more precise and repeatable results than hand-sharpening.

- They also enable you to quickly and easily adjust the sharpening angles to achieve the desired results.

- CNC grinders produce less waste material than other methods, which can save you money in the long run, particularly if you’re using carbide or another expensive metal.

- Because of the grinding wheels and grinding oils, it is less likely to cause heat-related damage to the tool or part.

HOW TO GET THE MOST OUT OF A CNC GRINDER

Here are some basic tips to help you get the most out of your CNC grinding machine:

- If possible, try to use a dedicated CNC grinder for sharpening your tools. This will help you achieve better results and avoid any potential damage to the machine.

- When sharpening a tool, always use the same grinding wheel. Switching between wheels can cause inconsistent results and may also damage the grinding wheel.

- Be sure to use coolant when grinding metal. This will help keep the tooling cool and prevent any heat-related damage.

- Make sure to inspect or test the sharpened tool on a scrap piece of material before using it on your workpiece. This will help ensure that the tool is performing as expected and that no further adjustments are needed.

SHOULD I PURCHASE MY OWN CNC GRINDER TO SHARPEN MY TOOLS?

Purchasing your own CNC grinding machine can be a worthwhile investment, but it’s important to weigh the pros and cons before making a decision.

Here are some things to consider:

- Do you have enough space in your shop to accommodate a large CNC grinder and coolant system?

- Can you afford the initial purchase price and ongoing operating costs? CNC grinders can be incredibly expensive to purchase and operate.

- Are you comfortable using the machine and do you have the necessary skill set to operate it?

- Is there someone in your shop who can help you operate and maintain the machine?

If you answer “no” to any of these questions, it may be best to leave tool sharpening to the experts at a company like Special Tools.

EXPERIENCE MINNESOTA’S PREMIER CUSTOM TOOL SHARPENERS

At Special Tools, our tooling experts have decades of experience using commercial CNC grinders and can help you get the most out of your cutting tools. At a time when the initial cost of these tools can be very high, we make sure you get your full use out of them by having them professionally sharpened.

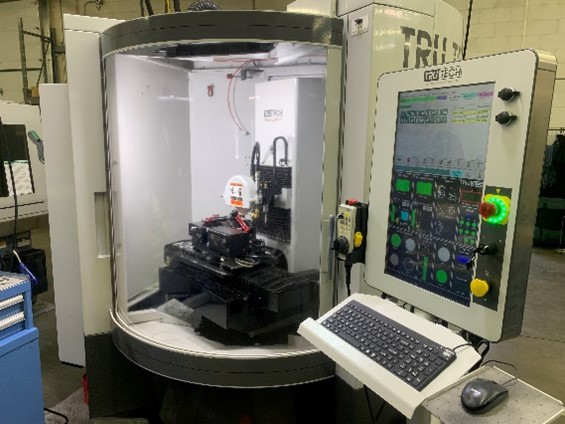

We primarily use one of our five ANCA CNC tool and cutter grinders to sharpen and produce all of the tools that come through our building. In addition, we use a TRU TECH Revolution OD Grinder to produce tight tolerance cutting tools that meet your exact specifications.

For more information on using a CNC grinding machine, or to see some of our other state-of-the-art custom tool sharpening equipment, please visit our Tool Sharpening page or contact us today.